Manufacturing IT Solutions and Services

We help manufacturers achieve higher efficiency and drive growth through our advanced IT solutions. We bring together modern technologies and industry best practices to optimize production lines, streamline supply chains, and boost overall performance. Our team will guide you in selecting, implementing, and managing the best-fit digital manufacturing solutions, so you can focus on what you do best – delivering quality products

Our Offerings

IT Consulting

Our IT consulting services focus on understanding your manufacturing processes and challenges. We work with you to identify the right digital tools and workflows that fit your specific operations. Whether it’s improving factory-floor communications or streamlining your supply chain systems, our team’s recommendations help you get the most out of every technology investment.

Manufacturing Software Integration

We connect your critical software systems so they communicate seamlessly and share valuable data. By integrating production management, inventory control, quality assurance, and logistics tools under one umbrella, you gain real-time visibility across the entire factory floor. This balanced ecosystem helps you spot inefficiencies, respond faster to changes in demand, and maintain smooth, continuous operations – all while cutting down on manual data handling and costly errors.

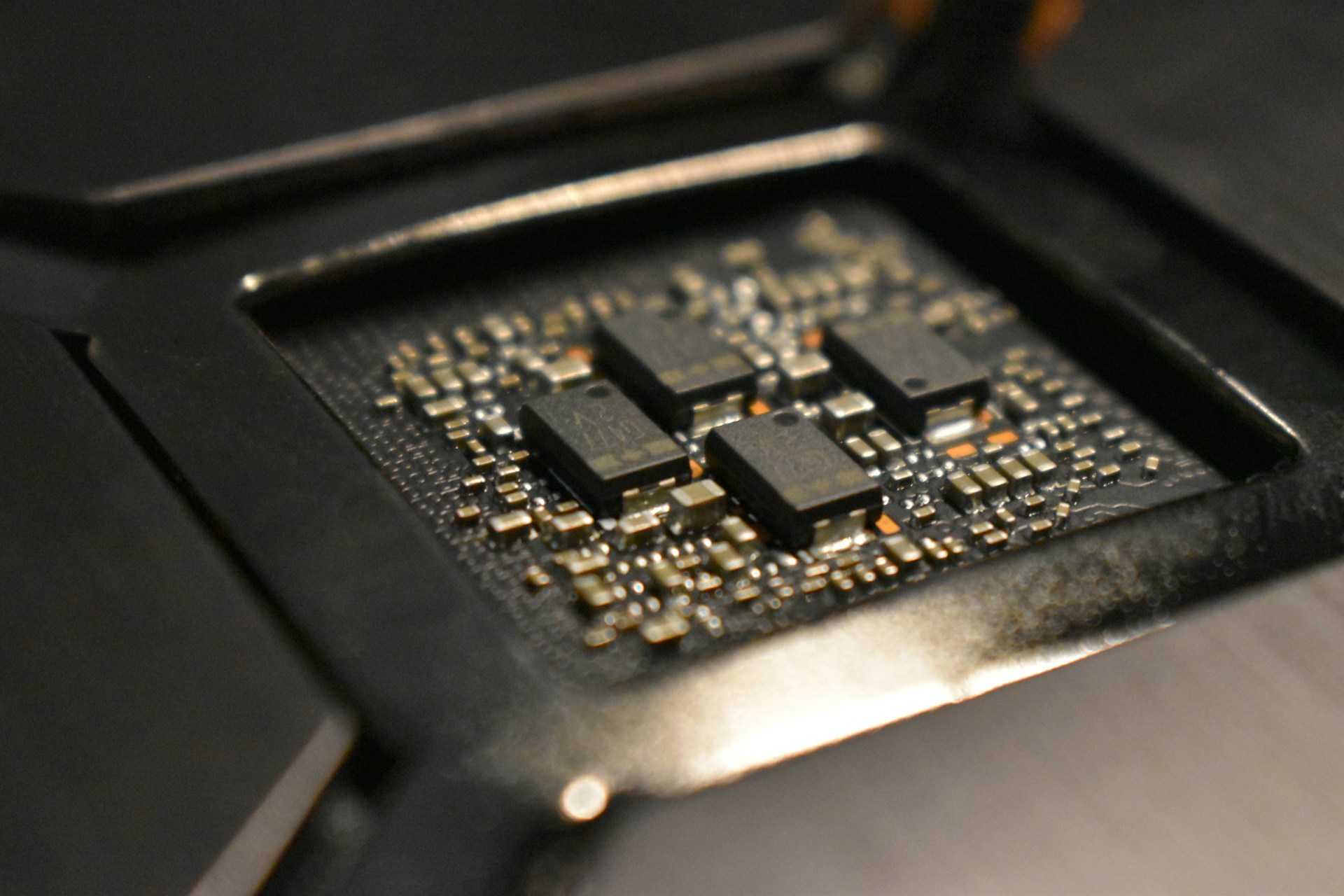

Manufacturing Predictive Maintenance

Predictive maintenance takes the guesswork out of equipment upkeep. Using advanced data analytics and machine learning models, we help you predict when machinery will need repairs, spare parts, or routine servicing. Instead of reacting after breakdowns occur, you can plan maintenance activities at just the right times. This lowers your risk of unexpected downtimes, improves workplace safety, and extends the lifespan of your equipment.

PLM System Development

A well-structured PLM system keeps everyone on the same page, from product designers and engineers to suppliers and service teams. We build solutions that trace each product’s journey from concept and design through production, distribution, and even disposal. By centralizing all product-related information, collaboration becomes effortless, product revisions happen faster, and quality remains consistent.

Condition Monitoring Software

Condition monitoring tools give you real-time insights into machinery performance. Our software continuously collects data on vibrations, temperatures, pressure levels, and other key indicators. With detailed, real-time insights into how your equipment is performing, you can identify issues early, prevent unexpected failures, and fine-tune operations for higher efficiency.

Custom Manufacturing Software

When off-the-shelf solutions don’t fully align your needs, we step in to build custom software designed around your exact specifications. From personalized inventory management apps to interactive dashboards visualizing your KPI data in a clear, actionable format, our development team ensures every detail supports workflows.

Industry 4.0 Solutions

As manufacturing enters a new digital era, embracing Industry 4.0 technologies gives you a powerful edge. We help you implement cutting-edge solutions that improve productivity, reduce costs, and open the door to innovation.

1

Artificial Intelligence

Artificial Intelligence drives smarter decision-making on the factory floor. From predicting maintenance needs to optimizing resource allocation, AI insights allow you to stay ahead of problems, streamline operations, and maximize output quality.

2

Cloud

Cloud-based platforms provide you with flexible, on-demand access to data and applications. Quickly scale up production, securely store sensitive information, and collaborate across different locations without heavy upfront investments in hardware.

3

3D Printing

3D printing technology enables rapid prototyping and on-demand manufacturing of custom parts. By shortening product development cycles and reducing material waste, it helps you bring new products to market faster and more cost-effectively.

4

Big Data & Analytics

With sensors capturing data at every production stage, Big Data analytics turns raw numbers into actionable insights. Identify patterns in equipment performance, detect production bottlenecks, and accurately forecast demand to make informed business decisions.

5

Augmented Reality

AR solutions offer technicians and operators real-time guidance right before their eyes. From hands-free equipment maintenance to immersive employee training, AR enhances accuracy, speed, and overall safety in the workplace.

6

Blockchain

Blockchain technology enhances trust and transparency in complex supply chains. Track components from their origin, verify product authenticity, and securely share transaction records, ensuring accountability and building stronger relationships with suppliers and customers.

Serving a Broad Range of Manufacturing Segments

We adapt our solutions to fit any manufacturing landscape. No matter what products you make, we have the expertise and technology to help you achieve greater efficiency, quality, and growth.

Ready to optimize your production process?

Our Experts Team Up With Major Players

Partnering with forward-thinking companies, we deliver digital solutions that empower businesses to reach new heights.

Our Workflow

We believe in a structured, transparent process that keeps you engaged at every step. By clearly defining goals, collaborating closely, and continuously refining solutions, we make sure that the technology we deliver truly meets your manufacturing needs.

Requirement Analysis

We begin by understanding your current operations, challenges, and long-term objectives. Through detailed assessments, we identify the tools and strategies that will best support your manufacturing goals.

Architecture & Design

With requirements defined, our experts design system architectures and workflows tailored to your needs. We map out how various components (software, equipment, data flows) fit together for optimal efficiency.

Development & Integration

Our development team builds and customizes solutions, then integrates them with your existing systems. This ensures seamless communication across your entire manufacturing environment.

Quality Assurance

We extensively test every solution to confirm it meets performance standards. This phase helps catch potential issues early, so your systems run smoothly when they go live.

Deployment & Training

We implement the finalized systems and train your team to use them effectively. By ensuring everyone knows how the new technology works, you see immediate value from your investment.

Continuous Improvement

Even after launch, we remain involved. We monitor performance, provide updates, and fine-tune solutions as your business evolves – keeping you agile, competitive, and future-ready.

Client Successes

Explore our case studies to see how our manufacturing solutions and services have empowered clients to achieve business results.

Get started with WiserBrand

Let’s begin your project journey

Get started with WiserBrand

Let’s begin your project journey

Prompt Response

We’ll contact you within 24 business hours to discuss your project

Exploratory Call

Join our team for a brief 15-20 minute talk about your needs and expectations

Tailored Proposal

We’ll present a customized proposal and recommendations for your project requirements

or

Pick a time that works for you, and let’s hop on a call